Väderstad Rapid

The Väderstad Rapid Coulter

Whether you are looking to direct drill, use minimum tillage or conventional tillage - the rapid drill coulter achieves perfect results in all systems.

Rapid isn't just the name -these perfect results are reliable even at very high working speeds. It can also handle everything from small-seeded crops such as oil seed rape, to large-seeded crops such as peas or beans.

Excellent depth control results in even emergence at all times. The single dsic seed coulter works together with the packer wheel - and also very high coulter pressure of 150kg - resulting in an exact seed placement. You may have noticed the agressiveness of the seed disc, this ensures a clean slot for the seed to be placed in. Two coulters are connected to each packer wheel with a parrallel linakge enabling the perfect following of ground contours.

Due to the offset mounted packer wheels the Rapid can cope with all soil types, ensuring the perfect depth at all times. Coping with light, medium or heavy soils, even in the same field is made much easier in combination with 'interactive depth control' which allows working depth alterations from the cab.

Ensuring The Perfect Start

The aggresiveness of the seed disc, and also the angle it works at ensures that the seed is placed next to fine soil - to ensure the seed-to-soil contact which is key to a timely germination.

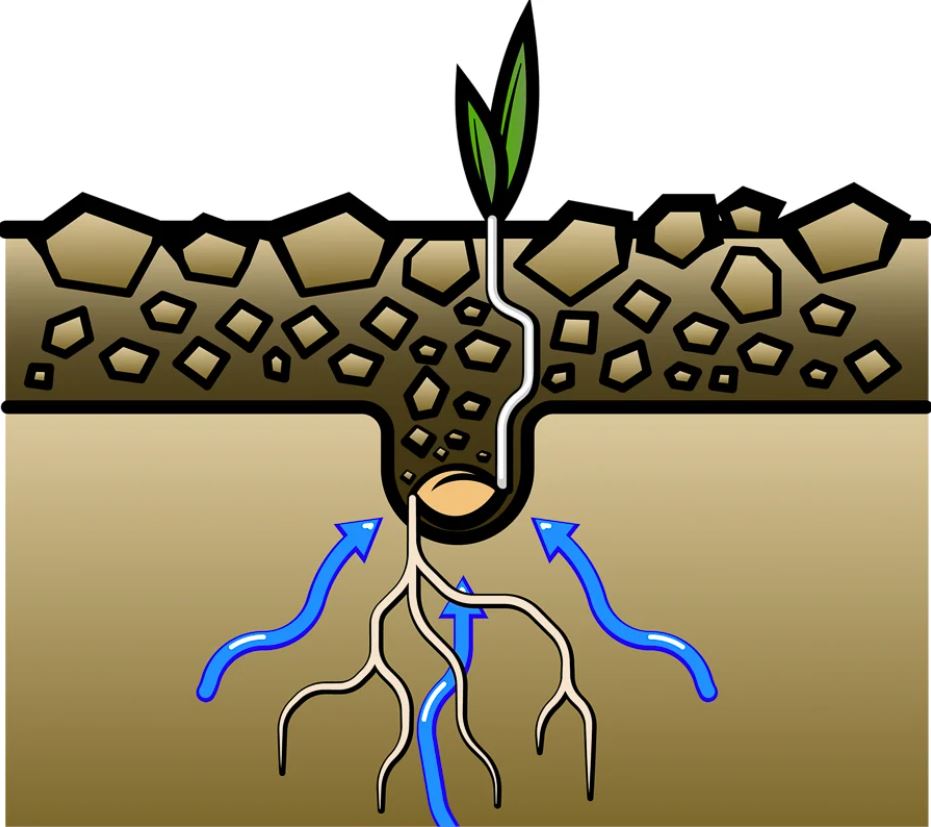

As the image shows the seed is placed below that of the level of cultivation - which means:

- the seed is placed in undisturbed soil - which allows better access to moisture

- the seed-to-soil contact is garanteed due to the soil which sits on top of the seed is fine soil, freshly aerated

- a clean seed slot is created, free of straw or other residues - giving it the best chance in the first stages of plant growth.

And to ensure the perfect start contiues the coulter suspension is maintnenace free, the steel used is quality long lasting Swedish steel , all bearings are grease free and the heavy-duty coulter has a hardened steel tip and a sideplate of tungston. All of these lead to less downtime, and lower running costs.